TAlign

The software TAlign determines the eccentricity and tilt of the workpiece axis. Between three different

methods can be chosen:

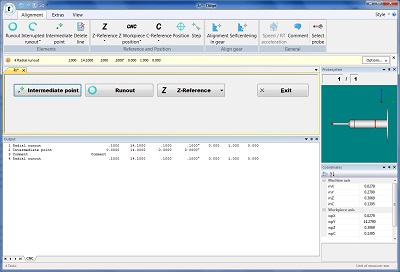

1. Axis determined by measurement of axial and radial run out on bearings, plane surfaces or holes.

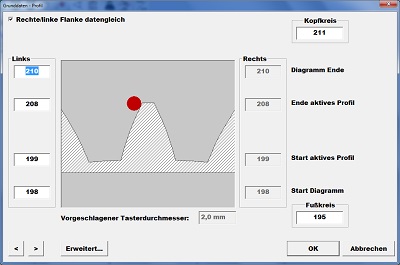

2. Axis determined by self-centering probe in tooth gap

3. Axis determined by measurement of single points (tech-in-programming), e.g. on tooth tip.

The measurement to establish the workpiece coordinate system is carried out on a physically rough aligned part. The maximum wobble error respectively the maximum eccentricity can be up to 2 mm.

This procedure reduces the time to align the part significantly.

TAlign operating modes

With the operating mode Teach CNC you can teach a CNC-run in order to run the alignment automatically. Run CNC starts the stored CNC-run. Finally Axis-Info starts the program Graftool with which you have the possibility to represent your measurement results in a graphical way as well as edit and evaluate them